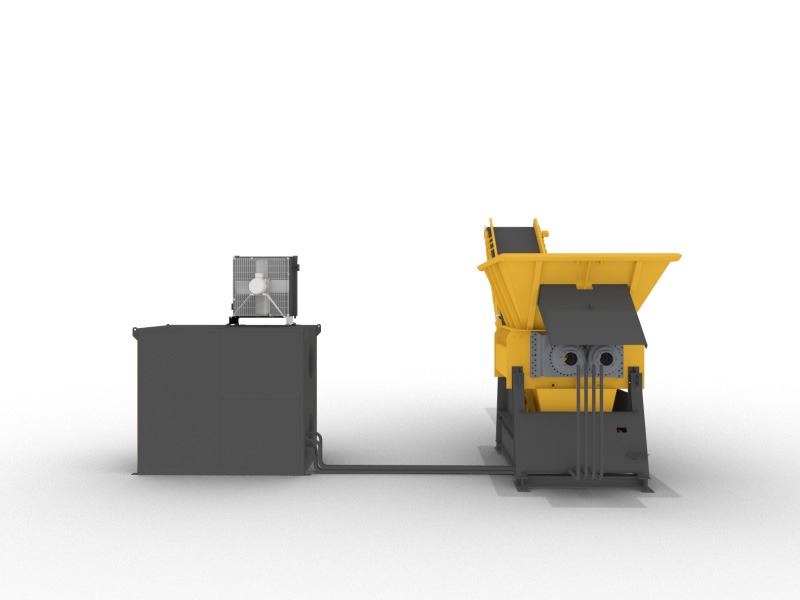

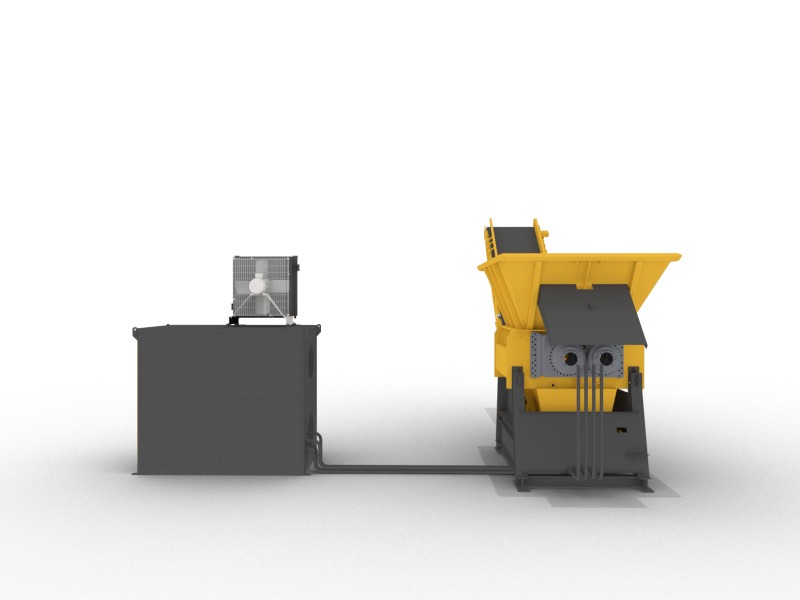

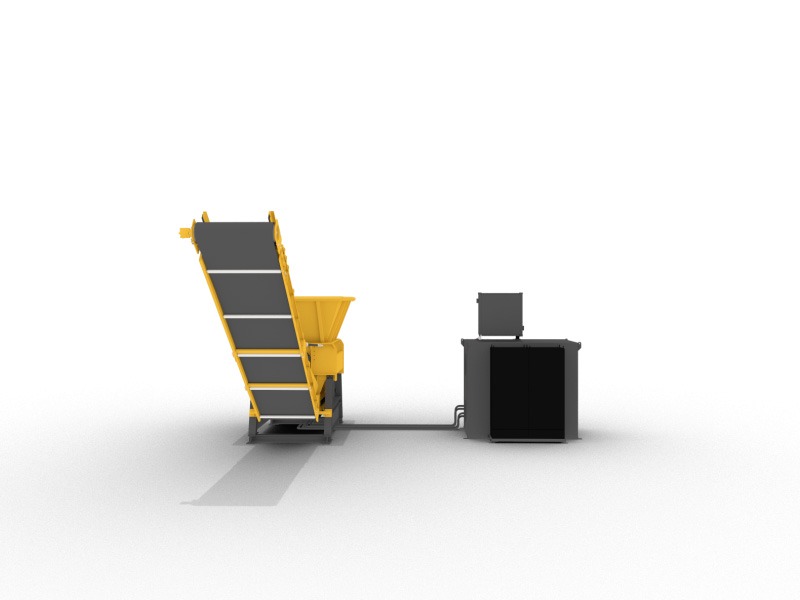

EUREC S MODEL 11.10 D (stationary e-pu)

KEY FEATURES AND OPTIONS

- Capacious infeed hopper equipped with hydraulicly lifted tipping table

- 190 KW (255 HP) diesel motor or 1 x 132 KW (180 HP) electric motor

- Stable frame below the tipping hopper protects tipping hopper, exhaust system and hydraulic cylinders

- Unique dual shaft design

- Triangular torque supports below the screwed side-arranged combs protects fixings from shea-ring

- Additional free space in front of the tool shaft bearings (open at the top and bottom). Winding and abrasive material does not get in direct contact with the shaft sealings, whereby the operational lifespan of the bearings increases considerably.

PRODUCT DETAILS

| Technical Data | |

|---|---|

| Drive performance: |

Diesel motor: ca. 190 kW Electric motor: 1 x 132 kW |

|

Gearbox: |

Patent EuRec |

| Nominal torque: | 110.000 Nm |

| Tools: | EuRec Patent |

| Speed: |

rated speed 15 - 32 rpm variable regulation 0 - 35 rpm |

| Throughput*: | |

| Domestic waste: |

up to 35 t/h |

| Waste wood: | up to 40 t/h |

| Industrial waste: | up to 20 t/h |

| *Among others, the throughput depends on material composition, requested output grain size and type of feeding. | |

AREAS OF APPLICATION

Shredders of the S 11 type shred reliably domestic waste, residual waste, industrial waste, bulky refuse, mixed construction waste, waste wood, demolition wood, logs and roots, cable drums, railway sleepers, pruning, plastics, aluminium profiles, scrap metal, roofing felt, bituminous sheeting, and many more. The tools undergo just a low wearing. Even difficult to shred materials like mattresses, carpets or tires are torn adequately. Organic components as part of the waste material are loosened during the shredding process and can be picked up by our Disc Separator in the course of a further treatment. We attach special importance to the design of different tools for different use and to the selection of the steel the tools are made of to reduce wear and optimize costs. It is an integral part of our know-how.

COMPARISON TABLE

|

S 11.00

|

S 11.05

|

S 11.10

|

|

| Radio remote control | √ | √ | √ |

| Tipping hopper | √ | √ | ο |

| Hopper extension | ο | ο | ο |

| Wheel axle without StVZO | ο | × | × |

| Special tools | ο | ο | ο |

| Breaker bar | ο | ο | ο |

| Discharge conveyor height > 4 m | ο | ο | ο |

| Conveyor belt monitoring | √ | √ | √ |

| Overbelt magnet (various) | ο | ο | ο |

| √ - inklusive ο - optional × - not applicable | |||

ADDITIONAL INFORMATION

ADDITIONAL SALES & SERVICES ASSISTANCE

Use One-click assistance for immediate assistance or additional information.