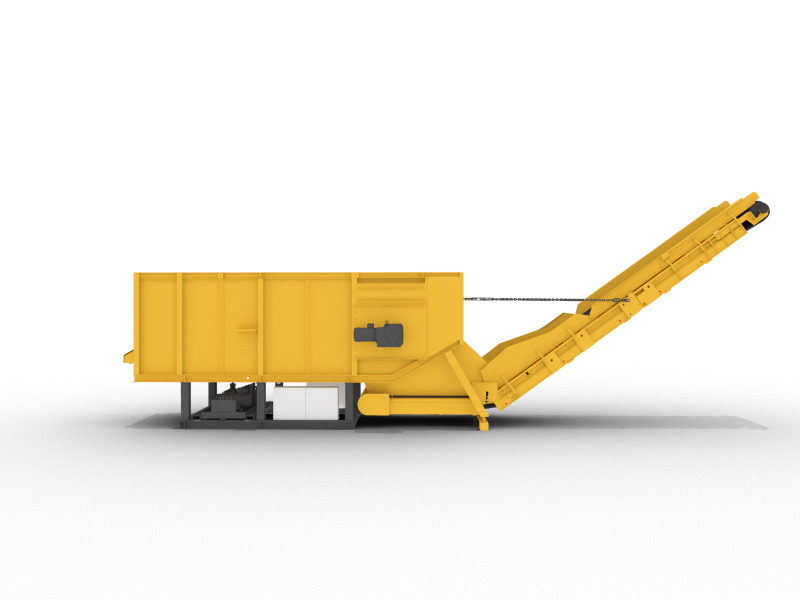

EUREC DOSING BUNKER ADS-1

KEY FEATURES AND OPTIONS

- Bunker housing designed as robust welded steel construction.

- Pushing floor with adjustable feed length, driven by double-acting hydraulic cylinders, feed speed and break time adjustable.

- Discharge chute to discharge material flow on discharge conveyor.

- Discharge conveyor with grouser belt, discharge height approx. 4,035 m at 36° inclination. Functional cabinet with hydraulic aggregate, cooler, hydraulic components and control cabinet below pushing floor.

- Manual and automatic operation possible.

- Bag opener optionally available.

- For a very large throughput, available with additional reversing conveyor mounted in horizontal position on top of bunker.

PRODUCT DETAILS

| Technical Data | |

|---|---|

| Layout: | Solid welded construction |

|

Number of dosing rollers: |

1 |

| Connected value: | 400 V, 50 Hz, approx. 31 kW |

| Dimensions: |

Length (discharge conveyor folded out): approx. 12 m Height: (discharge conveyor folded out): approx. 3 m Width: approx. 2.5 m |

| Total weight: |

pprox. 7.3 tons (without discharge conveyor) approx. 8.9 tons (with discharge conveyor) |

|

Electric control, hydraulics: |

Side-arranged, roofed control cabinet Hydraulics mounted below the bunker |

| Discharge conveyor: |

Grouser belt, belt width 1,400 mm Discharge height with 36° inclination: 4,035 mm |

|

Optionally available: |

Bag opener installed inside the bunker Reversing conveyor on top of the bunker Installation on low-bed truck for mobile use |

|

Bunker volume: |

approx. 12 m3 |

AREAS OF APPLICATION

Usually used as feeding and dosing bunker or intermediate bunker e. g. for feeding EuRec RBS-2, STS and DSK

ADDITIONAL INFORMATION

ADDITIONAL SALES & SERVICES ASSISTANCE

Use One-click assistance for immediate assistance or additional information.