EUREC Packaging System RBS-2

KEY FEATURES AND OPTIONS

- No use of nets, wire or metal straps

- Low film consumption

- Low consumption and operating costs

- Low wear and tear

- High compaction of material

- Either stationary or mobile use

- Prevention of gas and leakage water emissions

- No self-ignition of packed material

- High bale weight to save transport routes and staff costs

- Medium and long-term storage of bales inside and outside (in dependence on the chosen type of film)

- Preservation of the physical characteristics of the packed material

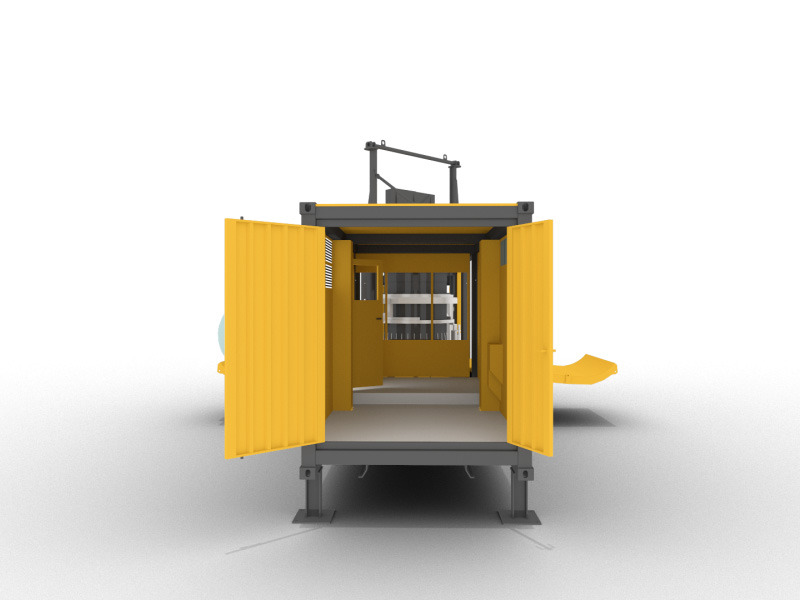

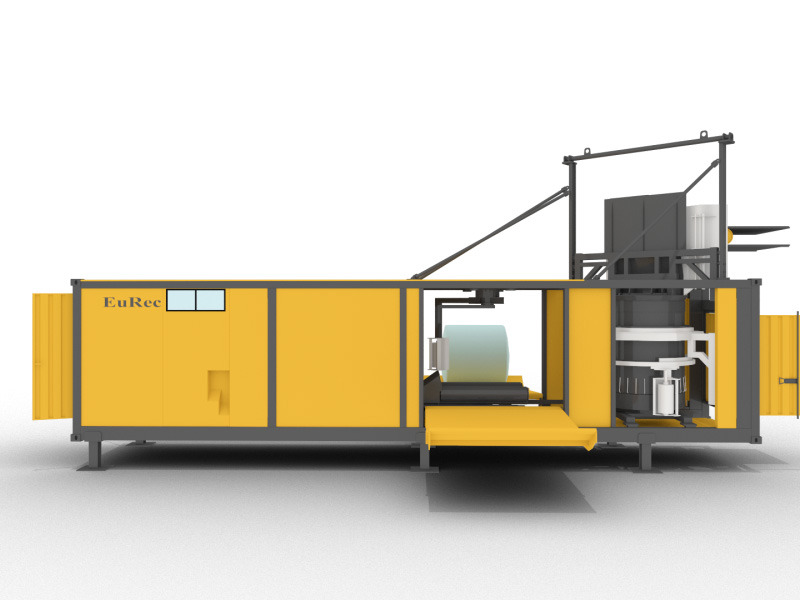

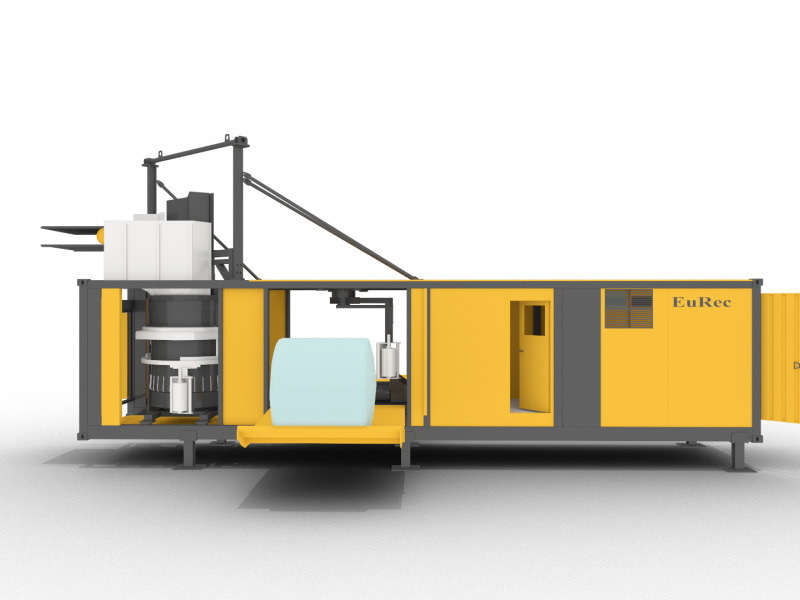

PRODUCT DETAILS

| Technical Data | |

|---|---|

| Total dimensions inclusive container lockings: |

40“ container Length: approx. 12.2 m |

|

Machine weight: |

approx. 23 tons without hydraulic lifting system |

| Bale dimensions (cylindrical): |

Diameter: 1.50 m |

| Bale weight: |

Substitute fuel: approx. 800 – 1,200 kg The data depends on composition and specific density of the material to be packed. |

| Bale discharge: |

At both sides of the RBS-2 |

|

Energy demand: |

Connected value: rotary current 400 V, 50 Hz |

| Process sequence: |

Fully automatic |

|

Used film: |

Material: LLDPE (linear polyethylene of low density) Width: 500 mm |

AREAS OF APPLICATION

Packaging of all kinds of compressible waste and recyclables, particularly suitable for domestic and residual waste, recyclables, substitute fuels, saw dust, various other types of waste

COMPARISON TABLE

What exactly makes a round bale packaging more advantageously than a square bale packaging?

We are often asked this sort of question, and with sententious facts, our answer is simple:

Round bales can be stacked much more stable than square bales. Even when stored close side by side, there is enough space between the bales for the bale gripping device to remove bales without damaging them. This is a direct result of the round shape.

- During the wrapping process, the film is stretched to the same extent all over the bale. There are no corners and edges, where the film may tear or protrude and where rain water accumulates or leakage water escapes.

- The volume of a round bale is essentially higher than the volume of a square bale, therefore, as the operator of a RBS-2, you save transport routes, lift truck equipment and staff costs.

- Per ton of material to be packed, the round baling method requires less packaging material than the square bale method.

- Because of the renouncing of nets, wire and metal straps, round bales can be opened up again much easier. In case of square bales, often a separate and expensive system is required to open the bales and remove the wire.

- Additionally, the container-shaped design of our Round Baling System speaks for itself. Transport and relocation on site become child’s play.

For further and project-related information, please get in contact with our sales team.

ADDITIONAL INFORMATION

ADDITIONAL SALES & SERVICES ASSISTANCE

Use One-click assistance for immediate assistance or additional information.